Parylene F CAS:1785-64-4

The versatile nature of Parylene F makes it useful across various industries such as electronics, automotive, aerospace, biomedical devices etc.. In electronic packaging, parylene coatings protect sensitive components by providing stress relief during thermal cycling, prevent corrosion under humid conditions, provide abrasion protection, and offer EMI shielding when required. For microelectronics encapsulation, thin films of parylene act as barriers between silicon chips and external environment which prevents contamination and oxidation. This enhances device performance and reliability. Automotive industry uses this material for wire harness coating that offers superior water vapor permeability resistant property at elevated temperatures compared to other conventional materials like Teflon. Aerospace application involves using parylene film as a conformal coating on printed circuit boards to improve their durability and maintain conductor integrity despite extreme environmental exposure. Medical field utilizes parylene because of its biocompatibility. Implantable biosensors often use parylene membranes allowing them to function without any adverse effect caused by human tissue. In summary, Parayleen F’s unique characteristics make it indispensable where long term stability, moisture sensitivity control, and reliable operation are critical.

| Composition | C16H8F8 |

| Assay | 99% |

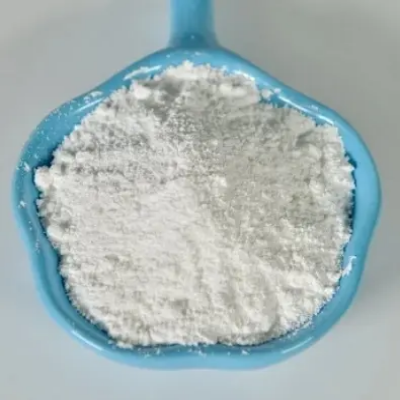

| Appearance | White power |

| CAS No. | 1785-64-4 |

| Packing | Small and bulk |

| Shelf Life | 2 years |

| Storage | Store in cool and dry area |

| Certification | ISO. |